Moving Bed Biological Filters

Moving bed biological filters, also referred to as moving bed biological reactors or MBBR’s, are ideal biological filters for ammonia and nitrite removal in aquatic systems. Moving bed biological reactors perform biological filtration in a controlled fashion but constantly keeping biological media in suspension with air, which oxygenates the water around the media and transports oxygen to the biofilm. This aeration simultaneously strip a portion of CO2 from the culture water, stabilising pH in the reactor and lowering CO2 levels for the culture species.

MBBR’s (Moving Bed Biological Filters) operate at very low head pressures, and commonly under gravity after a drum filter, reducing pumping costs dramatically. Their main advantage however is biofilm control and self cleaning. Due to the constant aeration, the media exfoliate against one another, removing waste and exfoliating old and inefficient layers of biofilm, keeping the nitrifying bacteria layer thin and young, for maximum ammonia uptake.

THE PURE AQUATICS APPROACH

Pure Aquatics have optimised our MBBR design and opperation by:

- Media choice

- Control of dwell times

- Optimising pipe sizes and minimising friction loss

- Careful control of dimensions and mixing requirements

- Superior biofilm control through advanced mixing

- Optimised aeration and circulation through diffuser design and material selection

- Media choice

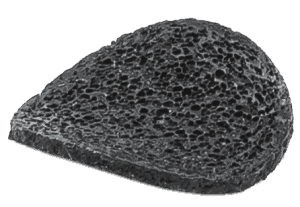

Our standard media we employ in our MBBR filters is the PAX-1 biological carrier, a standard design that is dimensioned for optimal mixing, water flow, water distribution, waste removal and biofilm surface area growth.

PAX-1 has a minimum surface area of 1000m2/m3.

Also available to utilise in our MBBR’s is the Hel-X Flake biological media, the chip/wafer style media was the first of its kind in the world, and Hel-X continue to lead the way in this style of biological filter media design and manufacture.

The 30mm Hel-X flake is over 5000m2/m3.

Hel-X can be applied at up to 100% of the media volume, but is also applied at between 10-30% as well to augment the biological filter capacity.

People wishing to increase their filtration capacity in their MBBR that utilise a 50% fill rate can add this media at 10% of the media volume to increase the filtration media volume to 60%

DWELL TIMES

Dwell time inside any reactor is critical, MBBR’s being no exception. The lower the dwell time (or higher the flux rate) the less ammonia and nitrite the filter will remove per pass, and could result in higher residual TAN levels in the tank.

Generally speaking, dwell times cant be too high, as long as oxygen levels are maintained and sufficient food (ammonia and nitrite) is supplied to the bacteria, some dwell times in wastewater treatment plants exceed 24-48 hours.

However, to maintain an increased dwell time a larger reactor (and potentially more media) is required, increasing construction and operating costs. Therefore, depending on the chosen effluent TAN level exiting the reactor, increasing the required size of the reactor to improve dwell time may or may not be required.

through careful design of the reactor overall, Pure Aquatics can design an MBBR for optimal dwell times and performance for any application.

REACTOR DIMENSIONS AND MIXING REQUIREMENTS

Reactor dimensions influence mixing inside the reaction chamber, pumping requirements for water flow, and injection depth for air flow.

Utilising the specially designed MBBR diffuser assembly and manipulating biological filter dimensions the Pure Aquatics design approach and MBBR filters achieve optimum results for ammonia removal for the target system requirements.

AERATION, MIXING AND BIOFILM CONTROL

Unless specified by the customer, all of Pure Aquatics MBBR filters utilise our newly developed MBBR diffuser assembly.

In the past, a plumbed hardline manifold of drilled pipe has been used for aeration of a moving bed, with very inefficient aeration and sub par circulation for the amount of air needed.

A variation of this approach is again a plumbed hard line manifold along the bottom of the reactor, but rather than using drilled pipe, membrane diffusers are used, improving circulation and aeration dramatically through the use of smaller bubbles, concentrated into streams spread throughout the reactor evenly.

This approach, although incredibly effective has 2 downsides, cleaning can sometimes result in technicians unintentionally breaking off diffusers, or when the diffuser finally does fail due to wear, a new diffuser needs to be fitted and possibly plumbing repaired.

This is not only a time consuming process can can also be expensive, requiring either a diver to install the new diffuser, or complete shut down of the filter while repairs are carried out.

Utilising Colorite Aerotube in a specifically designed self weighted configuration we have solved the above issues by making the diffuser assemblies not only removable for maintenance, but also mobile to allow the best positioning of the aeration and circulation.

By utilising the superior aeration and bubble distribution of colorite aerotube, we have also dramatically improved oxygen transfer, mixing and cleaning in our MBBR’s, whilst making set up, operation, maintenance and servicing easier.