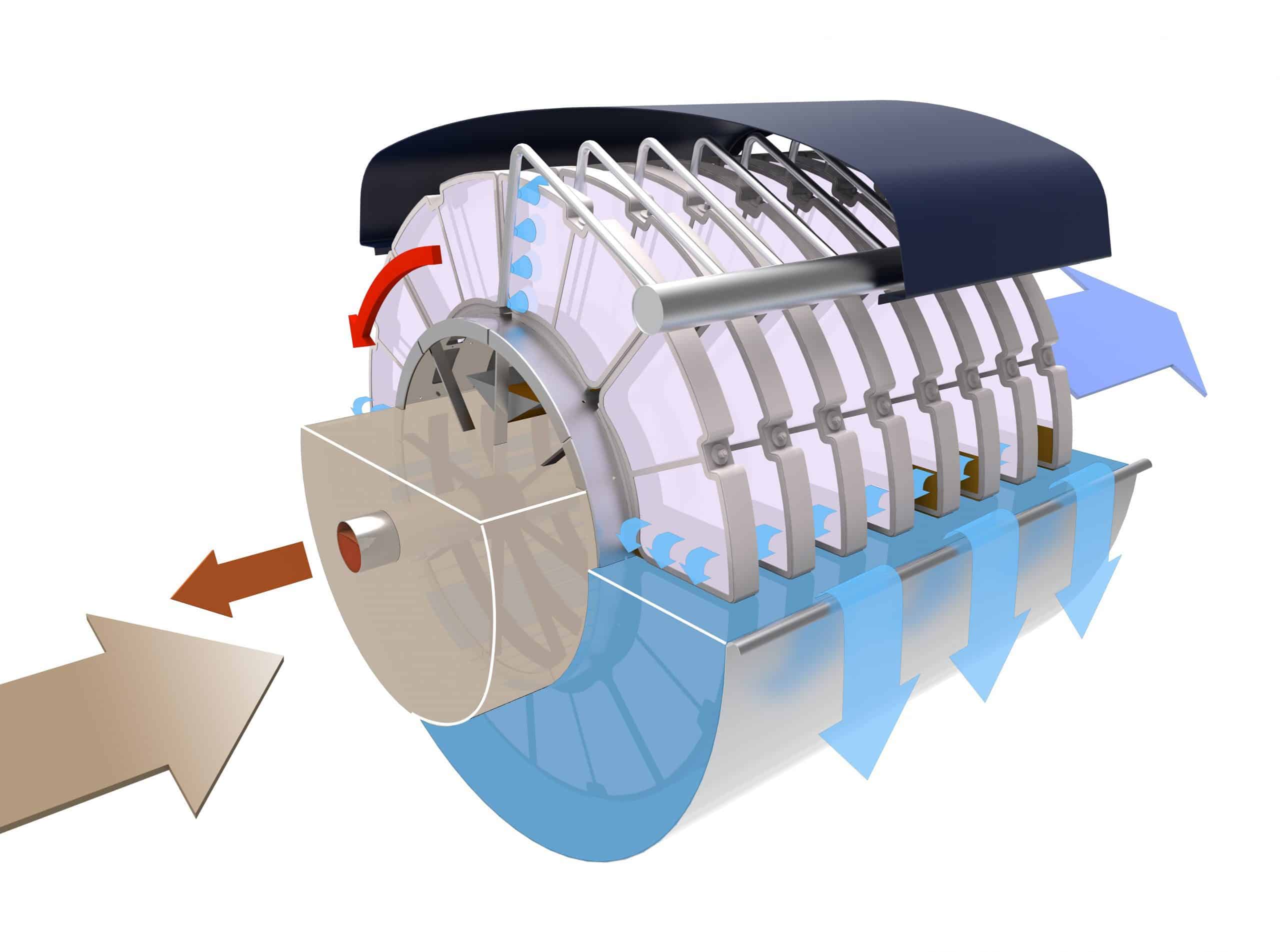

Trome Drum Filters

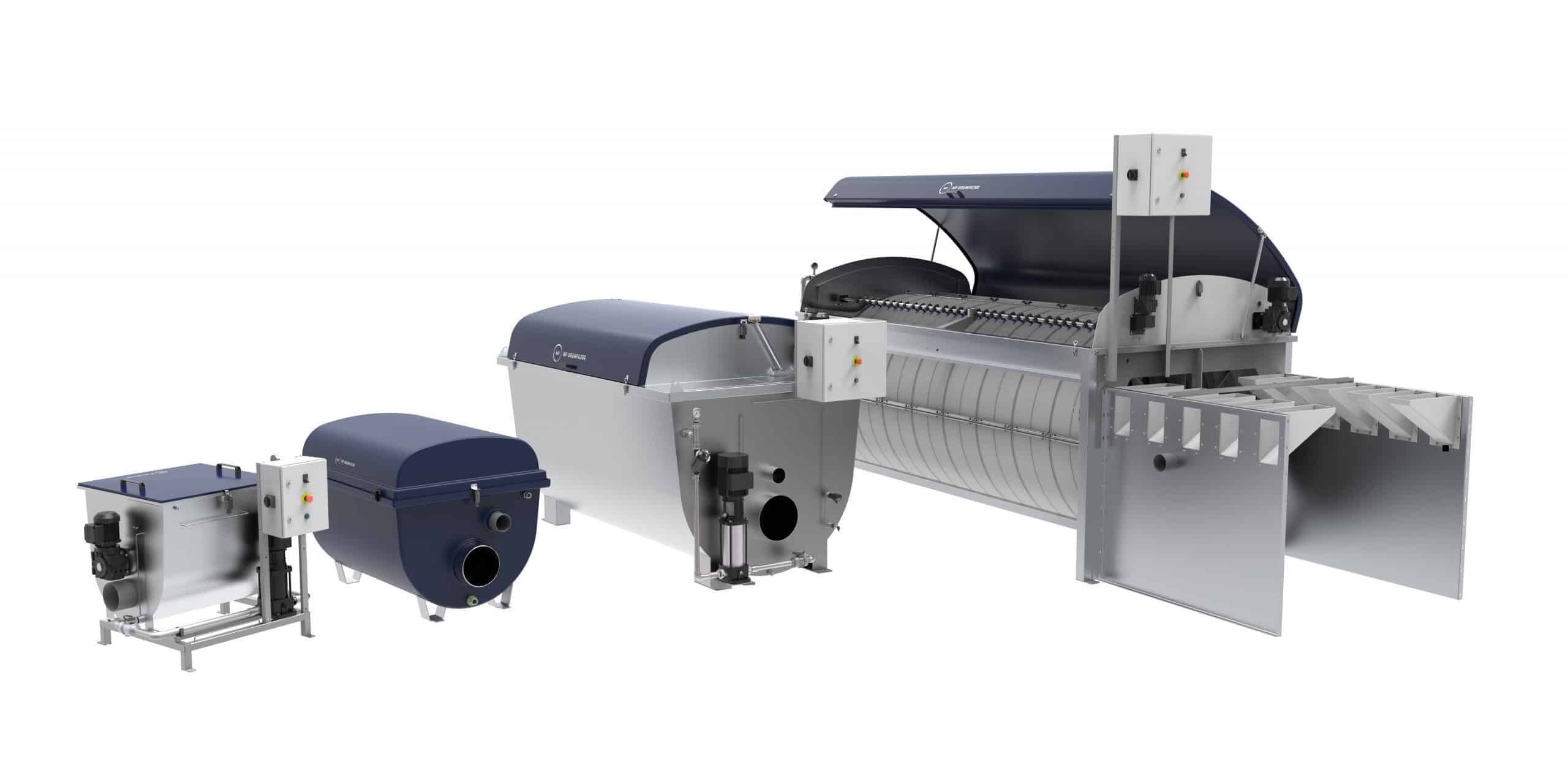

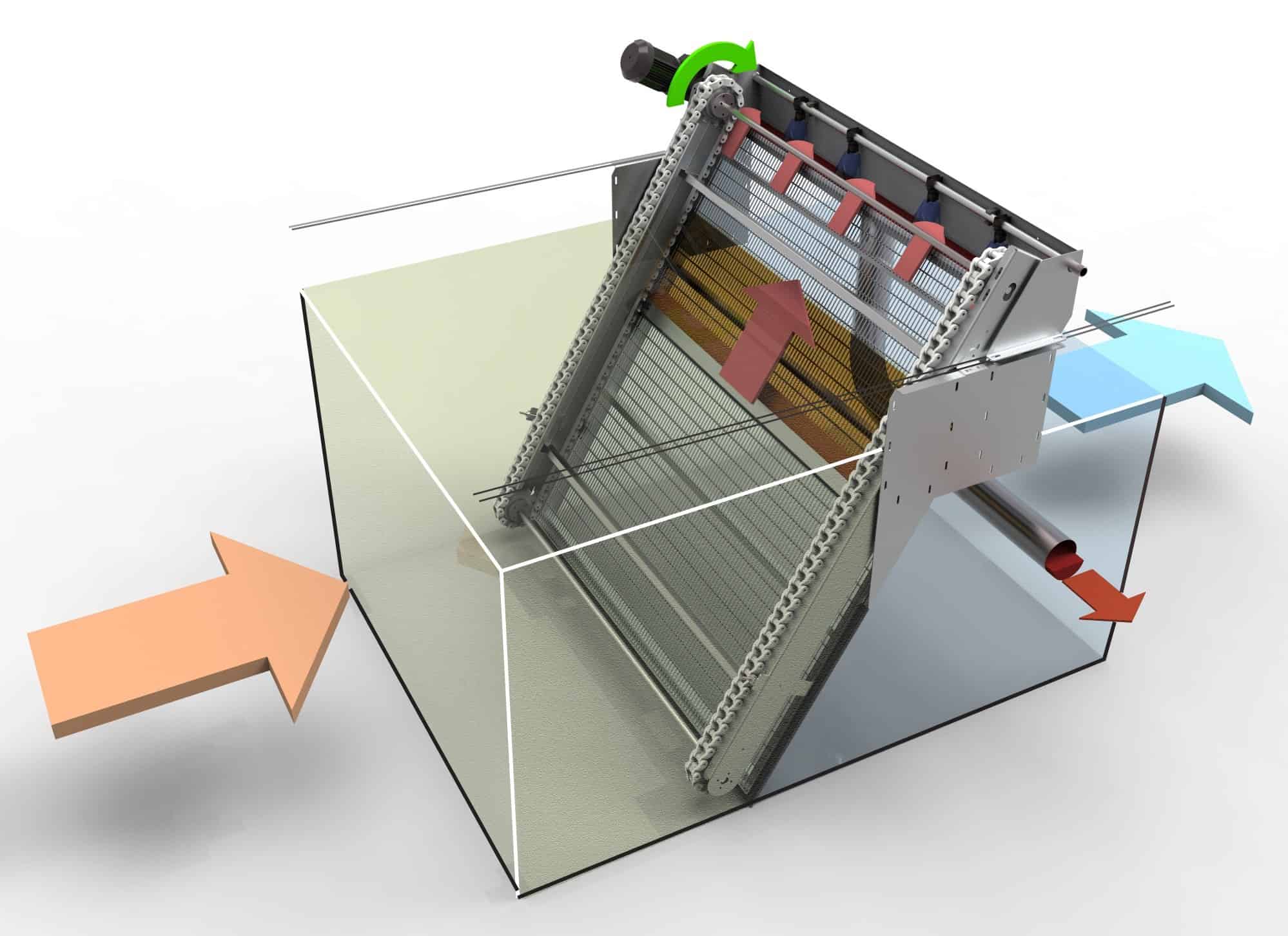

Trome Drum Micro Screen Filters are the industry standard for pre-filtration, solids and TSS removal in Aquaculture applications.

Together with our partners, Pure Aquatics offer accurate sizing of drum filters applied to specific applications and TSS levels whilst offering only the best in design and quality.

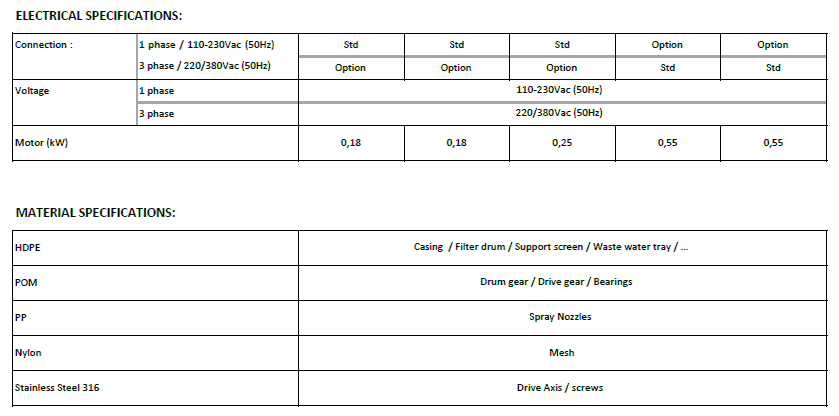

Trome Drum Micro Screen Filters offer a range that suits the smaller end of the market, opening up drum filtration to the smaller operator, quarantine and purging systems and research systems

Trome build HDPE drum filters that are completely saltwater compatible (also available with freshwater backwash pumps), their ability to construct smaller drum filters opens the technology to smaller application that would otherwise have to utilise filter matt or filter socks.

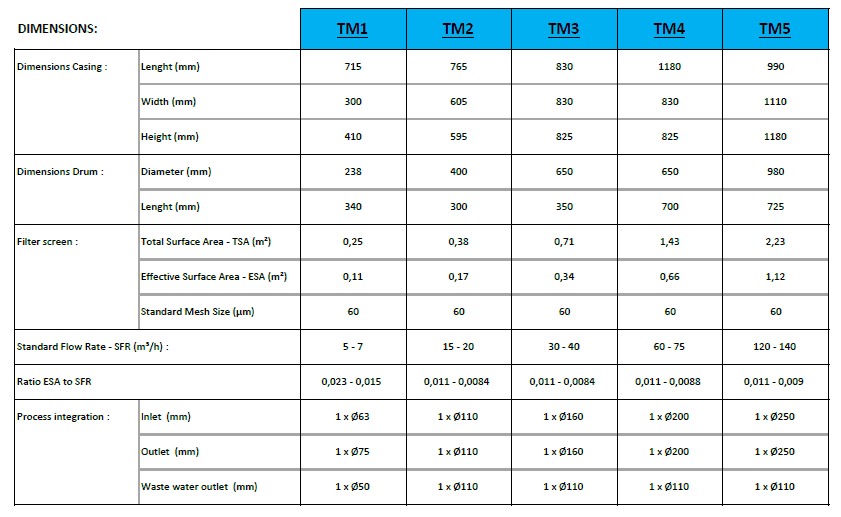

TM1 – 5,000LPH – 7,500LPH with 60 micron screens

TM2 – 15,000LPH – 20,000LPH with 60 micron screens

TM3 – 30,000LPH – 40,000LPH with 60 micron screens

TM4 – 60,000LPH – 75,000LPH with 60 micron screens

Trome was founded end 2013, inspired by a need in the aquaculture sector.

Drumfilters are used for many years in commercial fish farms where flow rates are multiple times higher. Most drumfilters on the market are designed for these larger RAS’s. These drumfilters are not suited for smaller and small scale RAS as can be found in research environments, hatcheries etc. Trome aims at these smaller RAS and with the TM1 the advantages of a drumfilter are now in reach of even the smallest RAS.

The new design, based on 5 years of experience in the field, together with the well thought combination of materials (HDPE, stainless steel, POM,…) results in a high quality, reliable and price efficient drumfilter that can be used in both freshwater and seawater environments.

Thanks to our extensive experience in aquaculture and that of our distributors, Trome will gladly advise you to ensure that the drumfilter best suits your needs.